Our Manufacturing Execution System (MES) products help you improve the efficiency and quality assurance of your production.

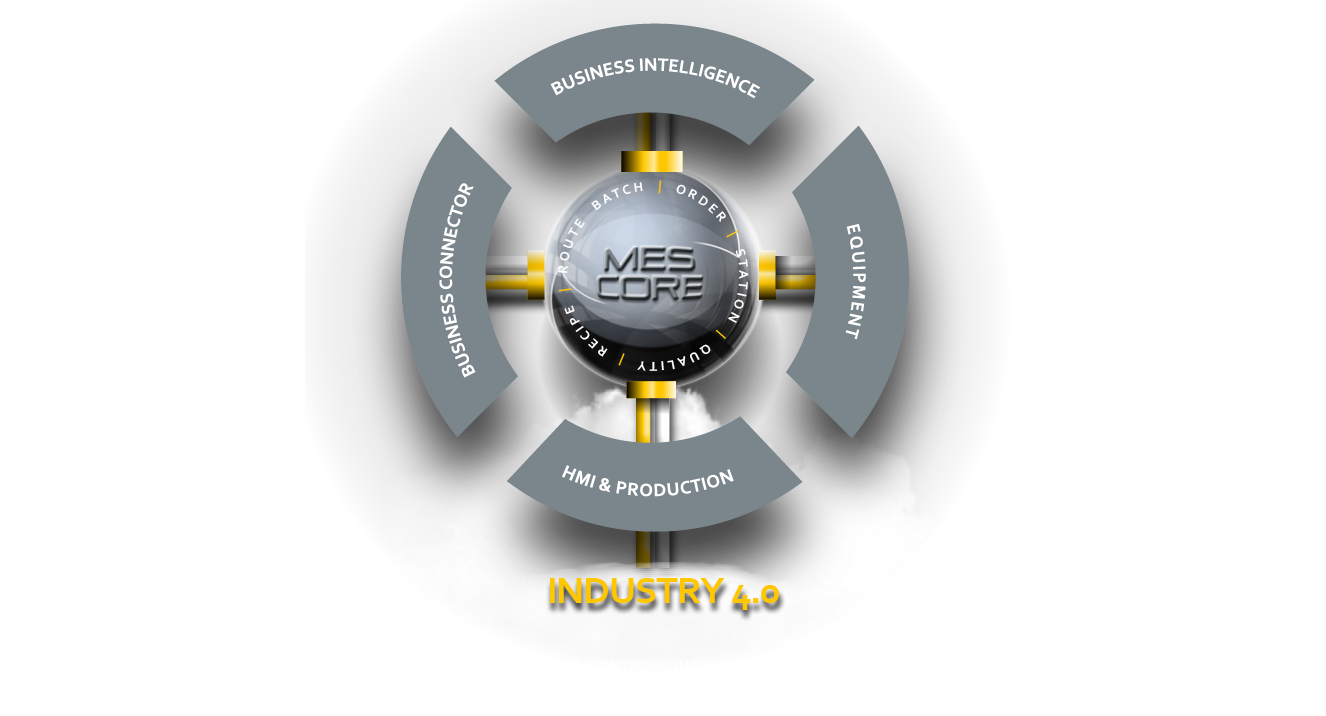

Given the current market requirements and the state of competition today, Lean manufacturing and increased productivity are key concepts in all kinds of manufacturing. The market for digital solutions in industry continues to expand, especially in the light of the tough competition that distinguishes the sector, and the ever-increasing demands for efficiency and profitability. Empir Industry’s Manufacturing Execution System contributes to improved efficiency, quality and traceability. From a purely technical perspective, the system creates a digital production flow that visualises the production process and links together the business system, machines and operators so they can communicate directly with each other. It is then possible to apply optimal control to production, ensuring that the refinement of the various products can be tracked and governed in every step of the process.

A manufacturing execution system (MES) is a computer-based solution used by companies within the manufacturing industry to control and monitor the process of product manufacturing in real time. The focus of the system and its optimization is always on the product.

In practice, this means that the MES manages, monitors, and synchronizes the implementation of the physical process steps carried out by operators, machines, and tools throughout the entire chain from order to finished product.

A fully-fledged MES solution has the ability to communicate with both equipment and operators on a second-by-second basis, which often requires a local installation in the factory.

MES helps to increase efficiency and productivity by providing real-time insights from the manufacturing process, so that the company can keep track of the quality of the products and minimize disruptions and errors.

It is thus an important tool for ensuring that the company delivers high-quality products to its customers in a cost-effective manner.

Partner from preliminary study to administration

We can assist with preliminary studies and analyses of the technological environment at the factory, and prepare a bespoke solution proposal based on this mapping work and our platform. Once we have found the right solution for the needs of the business, we commence work and implement the MES system at the facility.

Following implementation, we offer support agreements on the operation of the system – up to 24/7 – depending on actual needs. Empir Industry’s objective is to function as a close, long-term partner that is fully familiar with our customer’s core business, and which can make an active contribution to our customer’s improvement work over time.

Automated production with MES

Having day-to-day flexibility in our production system and the capability to quickly rebuild the production line are decisive factors in making us competitive. Therefore, we have demanding requirements, not only on integration with the business system, but also on flexibility regarding the make-up of the line. Since the implementation of the system, we have increased efficiency by 70%.

Stein-Are Kvikne, Flokk’s Production and Development Manager

“Quality defects are tough to spot”

“Quality defects are tough to spot”

An MES system provides quality assurance of the product in every step of the refinement process on the basis of predefined criteria. This makes it possible to spot quality defects quickly and facilitates rectification.

“We can’t spot disruptions to production in time”

“We can’t spot disruptions to production in time”

A production overview shows you the current production status in real time and can therefore help you pinpoint disruptions as soon as they occur.

“Our information and measurement data are defective”

“Our information and measurement data are defective”

MES systems are ideal for production follow-up. They make it possible to measure production at the facility over time, generate key figures and OEE figures, and measure lead times. All collated and visually displayed on the basis of the factory’s unique key figures.

“We need a straightforward view of the status of our production”

“We need a straightforward view of the status of our production”

A production overview is valuable to production, and one of the many benefits of MES. The system generates a real time view of the production flow, presenting the products in process (PIA), as well as machine status. It also visualises current status and key figures.

“Our manufacturing process often results in a lot of material waste”

“Our manufacturing process often results in a lot of material waste”

Elevated losses of material are often the result of difficulty in identifying quality defects. The MES system provides quality assurance of the product at every stage of the production process, which means you can quickly identify defects.

“We often have problems with overproduction, bottlenecks and long change-over times”

“We often have problems with overproduction, bottlenecks and long change-over times”

MES helps you optimise the production process on the basis of your current order status. The system generates management routines to ensure the right product is produced at the right time, and opens the door to just-in-time delivery.

There are a great many benefits to the MES system

Automated programme selection

MES automates recipe input, improving efficiency and reducing risks typically associated with manual input. In practice, this means that you avoid the issue of incorrect data input, problems with quality and performance, and difficulties that can arise on account of insufficient skills.

Station authorisation

Digital identification of the operator is performed at the station prior to start-up. This guarantees that the operator possesses the right skills for the station, which is important from the perspectives of safety and quality alike.

Material picking

Material picking is important in saving time; it is essential to pick the right materials in the right order. The system provides digital information about which products are to be picked in which order and from which location.

Assembly instructions

Visual and interactive instructions assist the operator with assembly tasks. Having the right information – which is also version-specific – at the right time helps prevent quality issues. It also reduces learning time, which can otherwise be protracted, and eliminates the risk of individual skill dependency which can arise in-house.

Traceability

Traceability is important from several perspectives; it is both a customer requirement and a legal obligation. It is also relevant to your own product and process analysis. MES generates digital traceability of work processes performed at all levels: operator, machine and product.

Preventative maintenance

In order to reduce shutdowns and other disruptions, the system communicates recommended measures to the operator in good time or at relevant intervals. In addition to preventing shut-downs, this also reduces maintenance costs which could otherwise be high.

Why Empir Industry?

Spotlight on industry since 1999

IT for the manufacturing industry has been our core business since we started back in 1999. Our superior skills in IT combined with in-depth knowledge of production and manufacturing makes us one of a kind.

Expertise always close at hand

As we see it, the working relationship does not end with the delivery of an IT system or service. Empir Industry is keen to be a long-term partner that provides support and advice with regard to operation and ongoing development. In our working relationships, the expertise of our IT consultants is always close at hand and available.

With a clear goal

We have the stated goal of using IT to help our customers become more competitive, and thus keep the manufacturing industry strong in the Nordic region. We develop our products and services to improve the efficiency of manufacturing processes and generate greater accessibility in production.

Ask me about Manufacturing Execution System

Daniel Johansson

CEO

+ 46 708-44 38 07